-

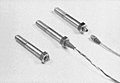

Force Sensing Bolts & Studs

force-sensing-bolts-studs

-

Strainsert Custom Bolt

Many Uses and Applications

- Measurement of Preload in Critical Assemblies

- Inspection of Preload after Assembly, Shipping, Prior to Use

- Provides Overload Detection Resulting from External Loading

- Used as Measurement Tool During Actual / Simulated Service Conditions (Shock, Vibration, Gasket / Joint Relaxation, etc.)

- Feedback to Control Systems

- Provides for Direct Analysis of Components Under Investigation.

Superior Technical Features- Small installation holes allow for greater load carrying capability

- Measurement Accuracy (<1% F.S., Typically.)

- Gage Installations are Two Patterns in Series, 180° Apart in Small Holes (Minimizes Errors Due to Bending and Torque)

- Quarter-Bridge and Full-Bridge Gage Installations with Ratings Up to 300° F Years of Experience Gaging Aircraft Quality Bolts and Many Other Types of Common and State of the Art Materials (MP 35N, Inconel, Monel, A286, Titanium, etc.)

-

Strainsert Custom Stud

Many Uses and Applications

- Measurement of Preload in Critical Assemblies

- Inspection of Preload after Assembly, Shipping, Prior to Use

- Provides Overload Detection Resulting from External Loading

- Used as Measurement Tool During Actual / Simulated Service Conditions (Shock, Vibration, Gasket / Joint Relaxation, etc.)

- Feedback to Control Systems

- Provides for Direct Analysis of Components Under Investigation.

Superior Technical Features- Small installation holes allow for greater load carrying capability

- Measurement Accuracy (<1% F.S., Typically.)

- Gage Installations are Two Patterns in Series, 180° Apart in Small Holes (Minimizes Errors Due to Bending and Torque)

- Quarter-Bridge and Full-Bridge Gage Installations with Ratings Up to 300° F Years of Experience Gaging Aircraft Quality Bolts and Many Other Types of Common and State of the Art Materials (MP 35N, Inconel, Monel, A286, Titanium, etc.)

-

Standard Internally Gaged Hex Head Cap Screws, SXS Series

To measure accurate preload, service load and overload of bolted assemblies

For maximum uniformity, efficiency and reliability in bolted assemblies

For effective research, testing and manufacturing of bolted assemblies -

Standard Internally Gaged 12-Point Cap Screws, SDH Series

To measure accurate preload, service load and overload of bolted assemblies

For maximum uniformity, efficiency and reliability in bolted assemblies

For effective research, testing and manufacturing of bolted assemblies

(Ferry Cap Counter-Bored Screws interchangeable with most Socket Head Cap Screws) -

Standard Internally Gaged Hex Head Cap Screws, SXA Series

To measure accurate preload, service load and overload of bolted assemblies

For maximum uniformity, efficiency and reliability in bolted assemblies

For effective research, testing and manufacturing of bolted assemblies -

Standard Internally Gaged Studs, ST Series

Accurately Senses Loads Induced in Studs

Detects Overloads in Assembled Equipment

Inexpensive Force Link Transducer

STRAINSERT ST Series Standard Studs employs an exclusive internal gaging technique (U.S. Patent #2,873,341) to detect the loads induced in them. This technique consists of the installation of foil type strain gages inside a small hole drilled along the longitudinal neutral axis of the Stud. This is far superior to the usual external gage installations both in mechanical and environmental ruggedness. Furthermore, a neatly miniaturized packaging is achieved by using the Stud itself to protect and seal the strain gage circuit. Still, this arrangement compares very favorably with the best external gage installations in accuracy and stability. Strainsert Studs, along with other internally gaged fasteners, were the first to provide the means for direct, accurate, and independent inspection of assembled structures under simulated or actual service conditions. Vibration and Shock loads, as well as static loads, on such assemblies can be easily measured to determine their structural reliability and integrity.