Unit of Measure

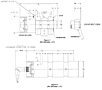

Dimensional Drawing

|

Performance Specs

|

Specifications

|

Electrical Specifications

|

General Information

Performance Specs

Overload without Zero Shift |

N/A 150% |

Overload without Failure |

N/A 300% (Minimum) |

Bridge |

N/A Full bridge 350 Ohm (Nominal) |

Excitation |

N/A 12 V AC (Maximum) 12 V DC (Maximum) |

| Output Signal1 | N/A 2-mV/V (Nominal) 2-mV/V (Standardized Output) |

Non-Repeatability |

N/A ±0.15% FS (Nominal) |

Non-Linearity |

N/A ±0.50% FS (Nominal) |

Hysteresis |

N/A ±0.50% FS (Nominal) |

Service Temp Range |

N/A to 150 °F |

Temp Effects (on Zero) |

N/A 0.005% FS / °F (Nominal) |

Temp Effects (on Output) |

N/A 0.008% load / °F (Nominal) |

| Zero Balance2 | N/A ±2% FS (Nominal) |

Specifications

Load Capacity |

N/A 100,000 lb |

Material |

N/A Stainless Steel 17-4, H-1025 (Standard) |

A - Width of Center Loading Section |

N/A 2 in |

B - Width of Clevis Support Section |

N/A 1-1/8 in |

C - Length of Pin/Bolt Reduced Section, Instrumented Zone |

N/A 11/16 in |

Dp - Nominal Pin Diameter |

N/A 2.748 in |

E - Active Length of Pin |

N/A 5-5/8 in |

F - Clevis Pin Head Length |

N/A 2 in |

H - Width of Keeper Plate Slot |

N/A 13/32 in |

J - Depth of Keeper Plate Slot |

N/A 1/2 in |

Lp - Overall Length of Pin |

N/A 8-3/8 in |

W - Allowance for Retaining Ring Installation |

N/A 3/4 in |

Keeper Plates |

N/A SPA-100-112-1-A |

Connector Type |

N/A Axial Connector Permanently Attached Axial Cable |

Electrical Specifications

Receptacle |

N/A PTIH-10-6P |

Mating Plug |

N/A PT06A-10-6S (SR) |

Function |

N/A Pin |

(+) Excitation |

N/A A |

(-) Excitation |

N/A D |

(+) Signal |

N/A B |

(-) Signal |

N/A C |

Cable |

N/A #20(26x34) AWG., rubber insulation, shielded, rubber jacket, 4-Conductor (Standard Cable) |

Function |

N/A Wire Code |

(+) Excitation |

N/A Red |

(-) Excitation |

N/A Black |

(+) Signal |

N/A Green |

(-) Signal |

N/A White |

- 1 Exact output provided with calibration data. (Standardized outputs are optional). In addition, Strainsert factory calibrations are intended to simulate installed conditions, however, it is recommended that an in-place calibration be performed to account for any installation, tolerance, and/or alignment influences affecting sensor measurement.

- 2 Prior to loading, it is necessary to initially/periodically null the zero load output to account for any residual offset.