Features

|

N/A

|

Specifications

Shackle Size |

N/A 2-1/2 Inch |

Load Capacity |

N/A 100000 lb |

Material |

N/A Stainless Steel 17-4, H-1025 (Standard) |

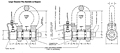

Dp - Nominal Shackle Bolt Diameter |

N/A 2.750 in |

AE - Shackle Opening |

N/A 4.13 in |

AE - Tolerance ± |

N/A 0.25 in |

BC - Width of Shackle Ear/D (Nominal) |

N/A 2.75 in |

C - Clevis Bolt Head Diameter |

N/A 3.250 in |

H - Inside Length of Chain Shackle |

N/A 8.00 in |

H - Inside Length of Anchor Shackle |

N/A 10.50 in |

R - Outside Diameter of Shackle Ear (Nominal) |

N/A 5.69 in |

T - Thread Size |

N/A 2-12 UN |

Shackle Type |

N/A Anchor Shackle Chain Shackle |

Connector Type |

N/A Permanently Attached Cable |

Performance Specs

Overload without Zero Shift |

N/A 150% |

Overload without Failure |

N/A 300% (Minimum) |

Bridge |

N/A Full bridge 350 Ohm (Nominal) |

Excitation |

N/A 12 V AC (Maximum) 12 V DC (Maximum) |

| Output Signal1 | N/A 2-mV/V (Nominal) 2-mV/V (Standardized Output) |

Non-Repeatability |

N/A ±0.15% FS (Nominal) |

Non-Linearity |

N/A ±0.50% FS (Nominal) |

Hysteresis |

N/A ±0.50% FS (Nominal) |

Service Temp Range |

N/A to 150 °F |

Temp Effects (on Zero) |

N/A 0.005% FS / °F (Nominal) |

Temp Effects (on Output) |

N/A 0.008% load / °F (Nominal) |

| Zero Balance2 | N/A ±2% FS (Nominal) |

Electrical Specifications

Cable |

N/A #20(26x34) AWG., rubber insulation, shielded, rubber jacket, 4-Conductor (Standard Cable) |

Function |

N/A Wire Code |

(+) Excitation |

N/A Red |

(-) Excitation |

N/A Black |

(+) Signal |

N/A Green |

(-) Signal |

N/A White |

General Information

|

N/A

Shackle Load Pins are strain gage transducers developed by Strainsert (U.S. Patent No. 3,695,096). They are manufacured utilizing the internal strain gage process perfected by Strainsert since 1960. They offer precision force measurement by simply replacing existing shackle pins. |

- 1 Exact output provided with calibration data. (Standardized outputs are optional). In addition, Strainsert factory calibrations are intended to simulate installed conditions, however, it is recommended that an in-place calibration be performed to account for any installation, tolerance, and/or alignment influences affecting sensor measurement.

- 2 Prior to loading, it is necessary to initially/periodically null the zero load output to account for any residual offset.